Startup’s ‘Made-in-India’ Li-Ion Battery Cells for EVs Can End Foreign Imports

In the first step towards making India self-reliant in meeting its future electric mobility goals, Bengaluru-based deep-technology startup Log9 Materials unveiled India’s first indigenously-developed cell manufacturing facility.

In an extremely critical improvement for the electric mobility area in India, Log9 Materials, a high level battery-innovation and profound innovation startup uncovered India’s first natively evolved cell producing office at their grounds in Jakkuru, Bengaluru, on 21 April 2022. The day additionally denoted the endeavor’s seventh commemoration since its initiation.

For what reason is it a particularly critical turn of events? Today, a larger part of the cells and batteries utilized in India’s electric vehicles (EVs) are imported from different areas of the planet like China and the European Union. This has two unfriendly ramifications for e-mobility in India. One, our grand e-mobility reception objectives are being held prisoner to different nations, also what it means for India’s import/export imbalance. Two, these batteries and particularly the cells utilized in them aren’t intended for Indian working circumstances which are very clear from ongoing fires and mishaps.

Talking at the revealing, Pankaj Sharma, fellow benefactor, said, “We are right now working with 11 unique hardware makers (OEMs) across various vehicle portions including 2Ws, 3Ws, 4Ws, trucks and transports. We are offering them battery arrangements (basically RapidX battery packs controlled by InstaCharge innovation) that will empower them to charge EVs multiple times quicker and in the span of 15 minutes, which is quicker than the time it takes to charge your cell phone. Simultaneously our batteries last quite a bit longer and proposition you execution and unwavering quality which is multiple times higher than your ordinary Li-particle batteries too, also that they can likewise endure outrageous climatic circumstances (- 45 to 60 degrees Celsius).”

Initiated as ‘Day Zero’ regarding the beginning stage of a possibly game-changing change in India’s EV area, Pankaj likewise noticed that their office “will be Southeast Asia’s biggest cell creation line”. With this new office, Log9 is planning to accomplish something like 50MWh of pinnacle cell creation limit in the following year, and afterward they would scale over 5GWh in the following 3-5 years.

Kartik Hajela, Co-Founder and COO, Log9 Materials, added, “When we at Log9 began our excursion, we might have either acquired based on what was available on the lookout and further based on it; yet we rather decided to chip away at a fresh start, and throughout the long term, with various preliminaries, blunders and disappointments, we have had the option to better our item and innovations. What’s more, today, with most extreme pride, we can declare that we have at long last left our imprint by bringing to India, the best battery and cell innovation accessible. India as a market requests items planned customized for the nation and not conveyed forward from another market.”

In the interim, fellow benefactor and CEO, Dr Akshay Singhal, said, “Our cells have been planned from the beginning in India. This implies that Log9’s cells and batteries are the most ideal for Indian working circumstances, environment and clients, and consequently they will assume a critical part in making India confident while assisting the country with understanding its aggressive electric mobility vision.”

Choosing Battery Cell Chemistry

Their state of the art indigenous cell production line for battery production is “completely versatile and adaptable to any chemistry or form factor,” notes Dr Singhal.

“India has very different requirements in terms of its climatic conditions, types of vehicles and the way we use them. Until now, we borrowed technology from the West and without applying our minds copy-pasted it into our vehicles not taking into consideration local conditions. When imported components don’t work, we complain about safety, reliability and performance issues. What we built for India today is not going to remain here. The same challenges and problems are being faced by countries across the world’s tropical belt. The problem is those leading battery innovators don’t even have the motivation to sell to us (India), forget about customising or building solutions ground up. We need to be self-reliant,” he claims.

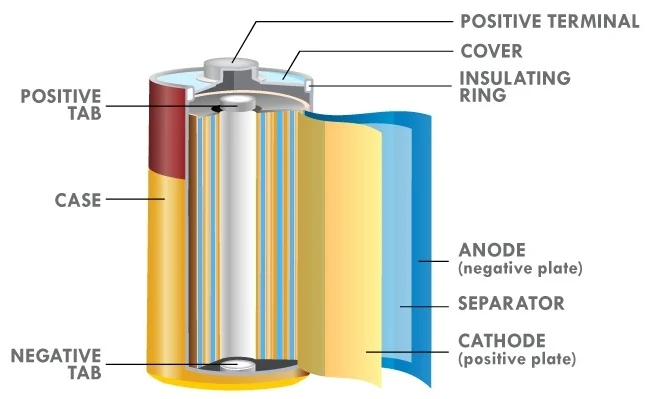

Basic to the most common way of assembling Li-particle battery cells for India’s to a great extent tropical climatic circumstances is the decision of cell science. Log9 is sending off its tropicalised-particle battery (TiB) upheld by lithium Ferro-phosphate (LFP) and lithium-titanium-oxide (LTO) battery sciences.

Not at all like LFP and LTO, the more well known NMC (Nickel Manganese Cobalt) science doesn’t have the essential temperature versatility to get by in Indian circumstances. Battery loads with NMC science in India are bound to experience the ill effects of warm out of control, bringing about flames.

“That is the explanation we must be cognizant about the sort of cell science we are deciding for building India’s confidence in energy capacity. LTO isn’t just temperature strong, yet in addition has an extremely lengthy life and is powerful. One more significant viewpoint to think about while picking cell science is the accessibility of materials,” says Dr Singhal. “Which materials can prompt better confidence according to India’s viewpoint? What regular assets are accessible in such manner?”

Talking at the occasion, Hemant Charaya, VP of battery cell innovation at Log9, said, “We don’t have the essential lithium saves that are expected for every one of the three cell sciences. Concerning NMC, we don’t have nickel or cobalt holds accessible in India. With regards to LFP, we have enormous stores of rock phosphorus, graphite, copper, iron and aluminum. With regards to LTO, we have titanium, aluminum and colossal stores of manganese that can go into the cathode.”

“In any case, it’s as yet a difficult assignment to ensure we get these materials in battery grade. While Log9 is working with scholastic establishments like IIT-Bombay, IIT-Delhi and IISc-Bangalore to foster these material cycles and redesign these materials to battery grade, we should have that decision of normal assets. Our TiB batteries can work versatilely in tropical climatic circumstances and can be worked with materials accessible in India. With this, we have decided to advance innovation headway in LFP and LTO cell sciences,” says Dr Singhal.

“With LTO, you get a science or arrangement which has a more drawn out life and offers quick charging. At the point when you progress with LFP innovation, you acquire the answer for cost effectiveness and long-range. Upheld with the mix of these two cell sciences, we can address every one of the prerequisites that we have whether it’s electric mobility, energy capacity or some other battery applications in any event, including space examination and investigation,” makes sense of Hemant.

How can Log9 address for Lithium accessibility?

There is a startup from their institute of matriculation IIT-Roorkee which has concocted another interaction to diminish the capital and functional use of lithium reusing and further develop proficiency.

“Called Metastable, it’s an organization spearheading in lithium reusing with a protected innovation that empowers over 90% material recuperation from Li-particle cells, decreases the capex of the interaction by 60% and improves opex by over 40%. This is a major advance in understanding our independence from a Li-particle innovation viewpoint since we don’t need to rely upon lithium saves outside India. Today, we have sufficient old Li-particle batteries meandering around in our environment for half of all our EV interest. There is monstrous potential for metropolitan mining and India can turn into a center for lithium reusing to deal with our nearby necessities,” says Singhal.

In the mean time, Log 9 has previously introduced the Li-particle cells made in their office into the inGO Electric bike. Everything about this bike was Made in India with the exception of the battery cell which they needed to import. The last missing piece of the riddle is presently with INGO Electric.

Talking at the occasion, Dr K Sivan, Ex-Chairperson, ISRO, drew an equal between ISRO pioneer Dr Vikram Sarabhai’s vision with Log9’s vision for what’s to come.